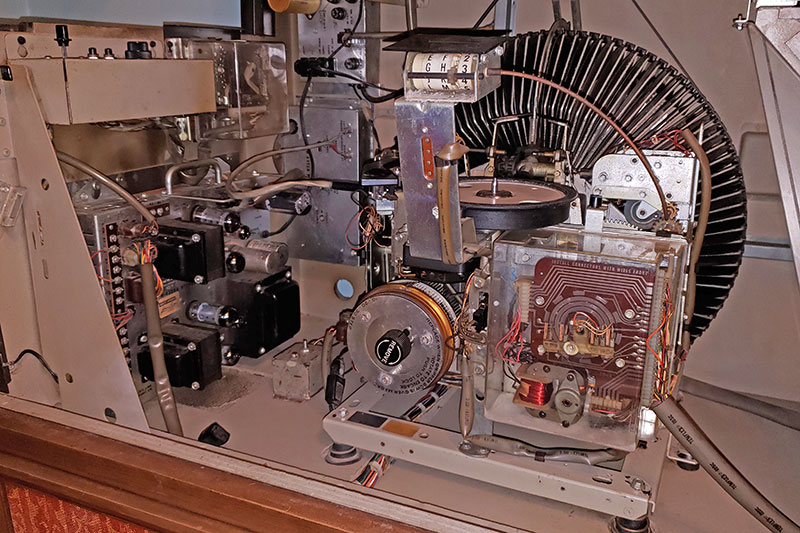

The service manual for the 1971 AMI/Rowe MM5 Presidential jukebox contains lots of useful information. I have trouble with the "Troubleshooting" pages. They are very nicely described, but I have problems identifying the parts they reference. You really do need the service manual, but this table was written to help me remember where the parts are and what I did.

| Problem |

Possible Cause |

Remedy |

| Credit and Selection System |

| Valid coins fail to pass through slug rejector into cash box. Coins remain jammed in rejector. |

Dirt or foreign matter clogging coin passages in rejector. |

Refer to coin rejector service manual for cleaning procedure. Clean in accordance with instructions. |

| Scavenger binding, rejector out of adjustment. |

Refer to coin rejector service manual for adjustment procedure. |

| Valid coins pass through rejector into coin box but credit is not established. |

Coin switch contacts dirty, bent, or broken. |

Adjust coin switches. Check for bent or broken contacts. Clean contacts. |

| Incorrect alignment of slug rejector or coin switches. Coins drop between switch levers. |

Be sure that slug rejector is firmly clamped in place. Adjust coin switches as necessary. |

| Credit coil plunger binding. |

Check credit coil plunger for binding due to dirt. Check coil windings for continuity. |

| Blown 0.6A fuse in credit unit. |

Check for binding coin switch. |

| Coin switch connector not seated. |

Check that connector is firmly seated. Check for broken wire in common line. |

| Valid coins are accepted but credit lamp does not light. |

Lamp burned out. |

Replace lamp. Check for broken wires. |

| Broken wiper blade on credit unit wiper arm assembly. |

Replace wiper blade. Check that credit unit edge connector is firmly seated. |

| Coins accepted; credits not registered properly-credit unit fuse blows. |

Coin hanging up on coin switch. Coin switch not opening. |

Check for jammed coin. Free binding coin switch. |

| Coin switch contacts closed by metallic foreign matter. |

Clean contacts and replace fuse. |

| Continuous free play. Credit light remains on. |

Credit coil plunger binding in raised position. |

Free credit coil plunger. Replace credit coil if necessary. |

| Cancel coil burned out. |

Check cancel coil for continuity. Check for burned appearance. Replace defective coil. |

| Cancel circuit open. |

Check credit cancel coil. |

| More than normal number of credits established for coin deposited. |

Appropriate stop coil not being energized. |

Check for intermittent open circuits, loose wires, or poor solder connections. |

| Appropriate stop coil plunger sticking. |

Manually actuate plunger to check for free operation. Clean or replace plunger or spring if necessary. |

| Improper credit set-up. |

Check pricing against credit and pricing chart. |

|

| Valid coins accepted, credits are established, pushbuttons do not latch in. |

Latch coil not operating. Select pulse and latch relay R1 not picking up. |

Check coil for continuity. Check relay contacts for closure. Replace relay or coil if necessary. |

| Select pulse and latch relay R1 contacts broken, dirty, or out of adjustment. R1 not picking up after credit is established. |

Clean and adjust relay contacts. |

| Open circuit between credit unit and select pulse and latch relay RI. R1 not picking up after credit is established |

Check for open circuit. |

| Pushbuttons latch in, but release prematurely; no selection played. |

Select pulse and latch relay R1 time delay circuit giving short pulse. |

Check diode on selector assembly. Check relay R1 for dirt between core and armature. Replace parts if necessary. |

| Pushbuttons latch in; no further action. |

Open circuit to search unit motor. |

Check wiring. |

| Pushbuttons latch in, search unit motor starts, but runs continuously. |

Open circuit in selector assembly, wiring from pushbutton switches to search unit printed board segments. |

Check selector assembly wiring. |

| Contacts on mechanism control relay R dirty, broken, or out of adjustment. |

Check mechanism control relay R for proper operation. Replace if necessary. This relay is nonrepairable. |

| Selection is registered magazine rotates one complete scan cycle and stops. No record is played. |

No circuit through stop switch. |

Check wiring to stop switch. |

| Selected pin not pushed far enough; select coil not properly positioned. |

Check inside and outside row select coils for proper operation. Adjust select coil arm assembly. |

| Wrong selection is played every time. |

Search unit select coil arm assembly out of adjustment. |

Adjust search unit select coil assembly. Check search unit wiper adjustment. |

| Stop switch out of adjustment. |

Check stop switch alignment. |

| Stop switch gear not properly installed. |

Check stop switch gear alignment. |

| One particular letter or number, in combination with all letters and numbers, will not register. |

Open circuit in the particular letter or number wiring. |

Check for dirt on search unit commutator board or wiper contacts. Clean with alcohol, if necessary. To locate the open circuit, make 20 selections in the following order: A1, B1, C2, D2, E3, F3, G4, H4, J5, K5, L6, M6, N7, P7, Q8, R8, S9, T9, U0, V0. This test combination will determine which letter or number has an open circuit. |

| Search unit motor energized but does not run. |

Search unit gears binding. |

Check for dirt or foreign matter lodged in gear teeth. Check backlash adjustment. |

| Tip of select coil plunger hung up on side of pin, excessive backlash causing select coil arm overtravel. |

Adjust search unit gears for proper backlash. |

| Only one selection is made but two selections play. |

Select coil plunger hitting two adjacent pins; select coil arms out of adjustment, or overtravel caused by excessive gear backlash. |

Adjust select coil arm assembly. Adjust search unit gears for proper backlash. |

| 50¢ coin establishes only 25¢ credit (50¢ bonus relay being used). |

50¢ bonus relay not picking up, or picking up and dropping out prematurely. |

Replace 50¢ bonus relay. Check that relay is firmly seated in socket. |

| Record Changer Mechanism |

| All selections register properly but magazine does not rotate. |

Scan Assembly not operating. |

Check scan coil for open, check for binding linkage. |

| Scan switch defective or out of adjustment. |

Check scan switch for proper operation, adjust switch position. |

| Diode D-1 open. |

Check by shorting across diode. |

| Cam switch CS2 faulty or out of adjustment. |

Check switch for proper operation or adjust switch position. |

| Magazine detent coil open or binding detent linkage. |

Check coil for continuity, free linkage. |

| Relay contact 1 & 9 faulty. |

Check relay, replace if necessary. |

| Detent switch faulty or out of adjustment. |

Check switch for proper operation or adjust switch position. |

| Magazine motor faulty or drive gears binding. |

Check motor and gear train for proper operation. |

| Scan linkage operates, magazine one complete scan cycle and stops - no record is played. Stop switch jumps pins. |

No circuit through step switch. |

Check stop switch and wipers on back of stop switch. |

| Diode D-2 defective. |

Check diode. |

| Short circuit in 50 MFD capacitor. |

Check capacitor resistance. |

| Faulty mech. relay. (R) |

Replace relay. |

| CS5 cam switch defective or out of adjustment. |

Check cam switch for proper operation - replace if necessary, adjust switch position. |

| Short circuit on common side of magazine detent coil. |

Check detent coil circuit. |

| Magazine stops at proper selection, but record transfer assembly does not operate. Relay (R) picked up. |

Open circuit to transfer motor. |

Check relay contacts 6 and 10, 7 and 11, for proper operation. |

| Defective transfer motor. |

Check motor, replace if necessary. |

| Transfer arm stops in mid travel between magazine and turntable. Phono power is on. |

Cam switch CS2 faulty or out of adjustment. |

Check for proper operation of switch. Replace if necessary. Adjust as required. |

| Blown fuse in junction box. |

Check 2—8/10 (2.8) and 6-1/4 (6.25) Amp fuse in junction box. Replace if necessary. |

| Transfer arm moves each selection record from magazine to turntable and back without being played, all other functions normal. |

Diode D-3 shorted. |

Check for short. |

| Short circuit in cancel line, cut off switch or automatic cancel circuit. |

Check for short. |

| Cam switches CS4 or CS5 faulty or out of adjustment. |

Check switches - adjust or replace if necessary. |

| Needle height improperly adjusted. |

Adjust height of needle. |

| Wrong side of record plays; selection is improperly registered. |

Center slip ring wiper broken or out of adjustment. |

Adjust or replace. |

| Left side switch in stop switch assembly faulty. |

Check left side switch - replace if necessary. |

| Toggle switch coil open or linkage binding. |

Check coil and linkage. Replace or free if necessary. |

| Diode D-3 open. |

Check diode. |

| Cam switch CS4 faulty or out of adjustment. |

Check switch, replace or adjust if necessary. |

| Mechanism relay (R) contacts 5 and 9, not making connection. |

Check relay — replace if necessary. |

| Wrong record played, selection is properly registered. |

Stop switch gear out of adjustment. |

Align 200 mark on stop switch gear with step in search unit mounting bracket.

|

| Stop switch out of adjustment. |

Align stop switch. |

| Selections play over and over, pins not being reset. |

Slip ring wipers No. 2 or 3 broken or out of adjustment. |

Adjust or replace slip ring wiper blade assembly. |

| Cam switch CS3 or CS4 faulty or out of adjustment. |

Check switches - replace or adjust if necessary. |

| Reset pawl out of adjustment. |

Adjust reset pawl. |

| Magazine scans continuously after last selection is played. |

Detent coil plunger binding or detent assembly out of adjustment. |

Manually operate plunger to check that the detent pawl locks the detent wheel. Adjust or replace if necessary. |

| Scan switch faulty or out of adjustment. |

Check switches, repair or replace if necessary. |

| Sound System

One thing I found while working on the jukebox is that a short between the center pin and sleeve of the RCA phono plugs into the preamp would result in that particular channel being muted. This can be tested for using a continuity meter. This was happening in the original RCA phono plugs which I replaced.

The original and new RCA phono plugs. |

| No sound. Phonograph mechanical operation normal. |

Blown amplifier fuse. |

Check for short or overload condition which caused fuse to blow. Replace fuse after this condition is corrected. |

| Faulty mute relay. |

Check operation of mute relay; replace if necessary. This relay is nonrepairable. |

| Cartridge leads broken or shorted. |

Check that both cartridge leads are intact and that all connectors and plugs are firmly seated. |

| Partial or distorted sound. |

Damaged stylus. |

Carefully check stylus, replace if necessary. |

| Incorrect remote speaker hookup. |

Check remote speaker connections. |

| Defective output transistors or tubes in either channel. |

Check output transistors or tubes. Replace if defective. |

| Partial short in local or remote volume control. Incorrect speaker hookup. Incorrect remote volume control hookup. |

Check volume control and speaker connections. |

| Low volume apparent in one channel. |

Cartridge detective. |

Replace cartridge if necessary. Check by substituting a cartridge that is known to be good. |

| Faulty preamplifier board. |

Replace preamplifier board. |

| Faulty driver board. (Solid-State Models Only) |

Replace driver board. |

| Balance control not properly adjusted. |

Adjust balance control for equal sound from each stereo channel. |

| Constant high volume, cannot be adjusted at volume control. |

Short in volume control circuit. |

Check wiring. |

| Excessive record scratch evident through speakers. |

Scratched or worn records. |

Replace records. |

| Damaged stylus. |

Check stylus force. Replace stylus. |

| Treble range control set too high for condition of records. |

Reduce treble range control setting. |

| Intermittent sound. Amplifier cycles on and off. (Solid-State Models Only) |

Overheated output transistors cause heat sensitive semi-conductors on heat sink to clamp amplifier input. |

Check for shorted or partially shorted speaker lines. |

| Check for component failure that may cause high heat dissipation in output stages. |

| Excessive hum - low volume. |

Broken shield on cartridge leads. |

Be sure that shielding or wires are not broken at any point between the cartridge and amplifier input plug. |

| 7868 tube failure. |

Replace tube. |