"U.S." Set

I do not know much about this set other than it was printed in Germany.

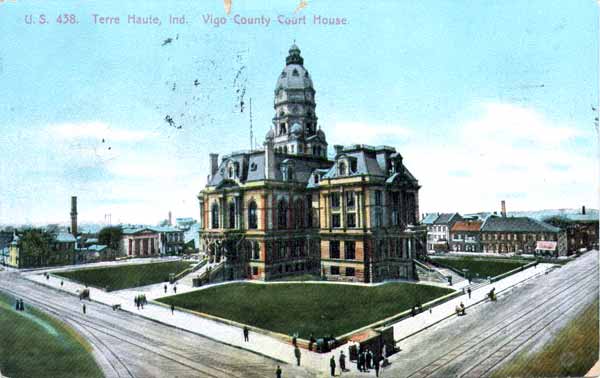

Vigo County Court House, Terre Haute, Ind.

This postcard was stamped in Terre Haute on November 3rd, 1917 and has the text...

U.S. 438

Printed in Germany

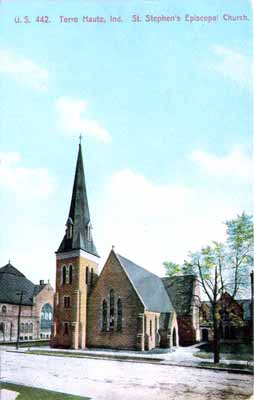

St. Stephen's Episcopal Church

This unused postcard has the printed text...

U.S. 442

Printed in Germany

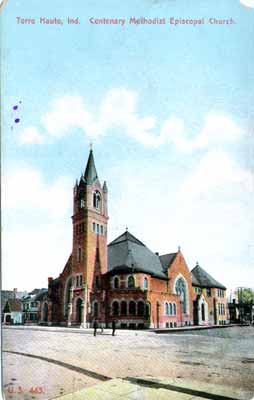

First Methodist Episcopal Centenary Church

This unused postcard has the printed text...

U.S. 443

Printed in Germany

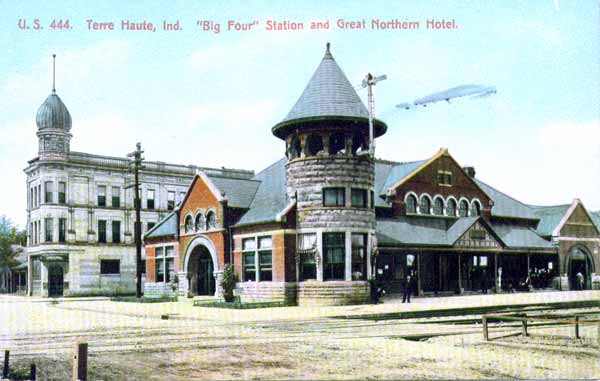

Big Four Station and Great Northern Hotel

This unused postcard has the following text...

U.S. 444

Printed in Germany

Behind the station can be seen the Great Northern Hotel. The hotel was originally called the Northern Hotel when it opened in 1899. It was renamed the Great Northern Hotel in 1907.

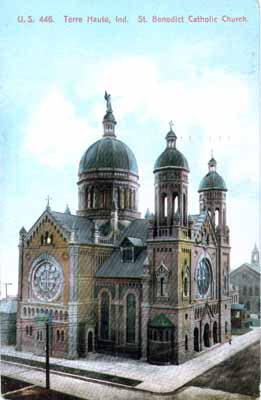

Terre Haute, Ind. St. Benedict Catholic Church

This postcard, stamped in Terre Haute on 20th September 1917, has the text...

US 446

Printed in Germany

Waterworks Plant

This unused postcard has the printed text...

US 498

Printed in Germany

In May 2008, I was contacted by Walt Fortner who provided the following information...

I know of four other Terre Haute cards (439 -Wabash River Bridge, 440 - City Hall, 441 - Country Club, and 445 - Fairbanks Library). I have also a number from the Portland and Columbia River area (504 - 530 and 535 and 537).

This page created 13th June 2008, last modified 4th January 2010